Diethylene Glycol (DEG): A Strategic Intermediate for Resins, Plastics, and Chemical Processing

Introduction:

Introduction:

Diethylene Glycol (DEG) is a widely utilized organic liquid valued for its stable behavior in processing, low vapor pressure, and strong affinity for water. These characteristics make DEG a dependable building block and formulating aid across manufacturing value chains. It is frequently selected for resin and polymer synthesis, heat‑management fluids, and moisture‑control systems where consistent performance and formulation flexibility are essential. Eurasia Petrol supplies high‑purity DEG aligned with international expectations, enabling customers in textiles, automotive, packaging, and chemical production to operate with predictable quality and efficient logistics.

What is Diethylene Glycol (DEG)?

DEG is a colorless, nearly odorless, moderately viscous glycol typically produced by partial hydrolysis of ethylene oxide. It is fully miscible with water and many polar organics, dissolves select resins and plasticizers, and blends easily with other glycols. Thanks to its hygroscopic nature and high boiling range, it functions both as a reactive raw material and as a versatile process solvent.

Key Properties of DEG:

- Reliable solvency for numerous resins, plasticizers, and additives

- Hygroscopic liquid with excellent water compatibility and moisture retention

- Low volatility with a high boiling range that supports elevated‑temperature operations

- Miscible with water, alcohols, and many oxygenated organics; blends readily with other glycols

- Stable handling characteristics under standard storage and transfer conditions

Industrial Applications of DEG:

Diethylene Glycol contributes to a broad portfolio of industrial uses:

- Polyester and Alkyd Resins: Acts as a diol component to tailor flexibility, clarity, and processing windows.

- Plasticizers and Polyurethane Systems: Serves as an intermediate that supports softness and compatibility in finished materials.

- Antifreeze and Coolant Packages: Helps manage freezing and boiling characteristics in engineered heat‑transfer fluids.

- Humectant and Conditioning Agent: Retains moisture in formulations used in textiles, paper, tobacco, and select personal‑care products.

- Chemical Intermediates: Participates in esterification and etherification routes for specialty solvents and additives.

- Gas Dehydration and Treatment: Applied as a dehydrating medium in natural‑gas processing under defined operating protocols.

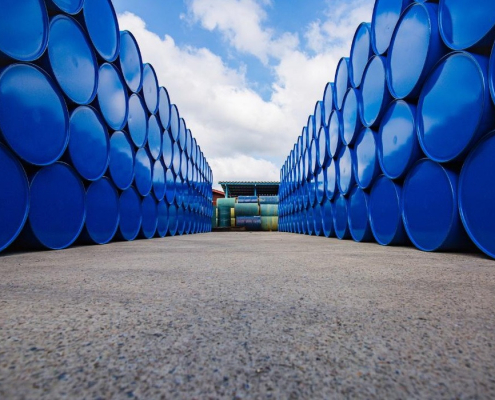

DEG Supply by Eurasia Petrol:

Eurasia Petrol maintains a vetted sourcing network and rigorous quality oversight to deliver consistent DEG supply. Material is procured from reputable global producers and qualified through specification checks before release. With warehouse capacity strategically located in Türkiye, we support short lead times, steady availability, and shipment flexibility for customers throughout Europe, the Middle East, and adjacent markets. Our commercial and technical teams collaborate to match grade, packaging, and transport modes with each project’s operational needs.

Why Choose Eurasia Petrol?

- Assured sourcing from established international producers

- Documented quality consistency with pre‑dispatch controls

- Competitive commercial terms and reliable scheduling

- Customer‑centric logistics coordination and responsive technical guidance

Conclusion:

DEG provides manufacturers with a dependable, adaptable diol that supports both reaction pathways and formulation targets. Its solvency, moisture‑management behavior, and thermal performance make it a practical choice from resin lines to heat‑transfer systems. By partnering with Eurasia Petrol, buyers secure access to a controlled, on‑time supply that aligns with operational constraints and quality expectations across modern manufacturing environments.